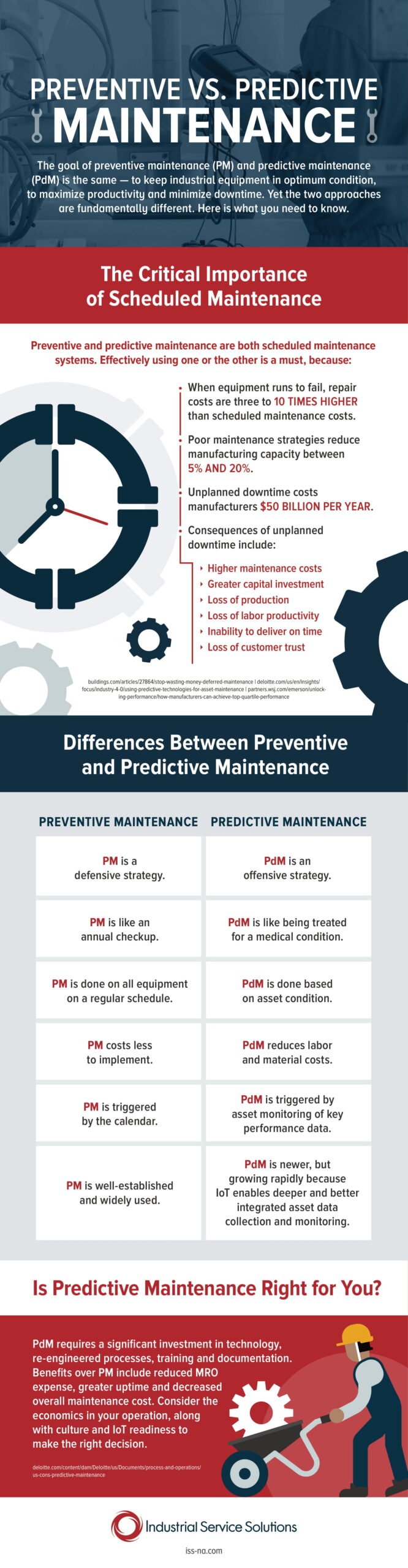

The Impact Of Maintenance On Equipment’s’ Longevity

In order to ensure any manufacturing operation’s success, organizations have to prioritize a maintenance schedule that fits the needs of their business. This decision is usually left between two strategies, preventive and predictive maintenance. While they both might be different in how they achieve it, they both have the same goal. Ensure the health and integrity of all equipment for the long-term.

Finding the right strategy for your organization can be tricky, so it’s imperative to understand how these strategies operate and how they can potentially benefit your business. Preventive maintenance seems like the best place to start as it is the more common of the two. This strategy approaches maintenance as a one-size-fits-all dynamic. Meaning that each piece of an organization’s equipment will possess a maintenance interval derived from its characteristics and flaws. So, while every interval is bound to be different, they’re derived the same way. For example, newer pieces of equipment will likely require less maintenance than older pieces of equipment, perhaps one check-up throughout the year. Whereas the older pieces of equipment an organization owns will likely require more check-ups throughout the year.

The alternative is a much more effective maintenance approach for organizations hoping to maximize their maintenance resources. Predictive maintenance strategies require sophisticated systems capable of connecting to an organization’s fleet or equipment. Once connected, these systems are able to collect and analyze output data of each piece of equipment. This data is then able to indicate when a machine will face critical failure and what maintenance is required to prolong that failure. The efficiency that these systems provide comes at a steep cost, though. As these system’s barriers to entry are high, many organizations are unable to integrate this maintenance approach.

Even with such insurmountable costs, the implementation of these systems continues to become easier. The organizations that can afford these systems are leading the way in that effort. These systems are connected to the Internet of Things, meaning as more and more machines become compatible and are added onto this network, the more accurate the information derived from the equipment can be. With more accurate reporting, comes more accurate insight into what is causing a piece of equipment troubles. Identifying this trouble makes mitigating the risk of failure much more likely for these organizations. Which can lead to decreased down-time for any piece of equipment.

Despite their advantages, as mentioned previously, cost will often keep organizations from benefiting from predictive maintenance systems. For some organizations, this inaccessibility is actually a benefit. Disregarding the cost for a moment, organizations would have to adapt in other means when utilizing a predictive maintenance system. For example, integrating these systems into existing organizational processes can be difficult. What’s even more challenging, though, is retraining employees regarding these systems. For some tenure employees, this could mean asking them to completely reconsider everything they’ve known about maintenance to the day. Certainly not an easy task for any employee. With that being said, if you believe your organization is capable of investing the capital and have enough trust in your employees to make the transition smooth, predictive maintenance is the route to take.

If you’re still on the fence regarding predictive maintenance systems, be sure to take some time reviewing the infographic accompanying this post for more information regarding the advantages and disadvantages of transitioning. Courtesy of Industrial Service Solutions.